In May and June Q8Oils’ Blending Plant in Antwerp (BPA) had the pleasure to welcome two MBA-students of Vlerick Business School. Their assignment was to create a current state value stream map of the filling process for 20 liter pails. Their final recommendations contribute to Q8Oils’ continuous improvement.

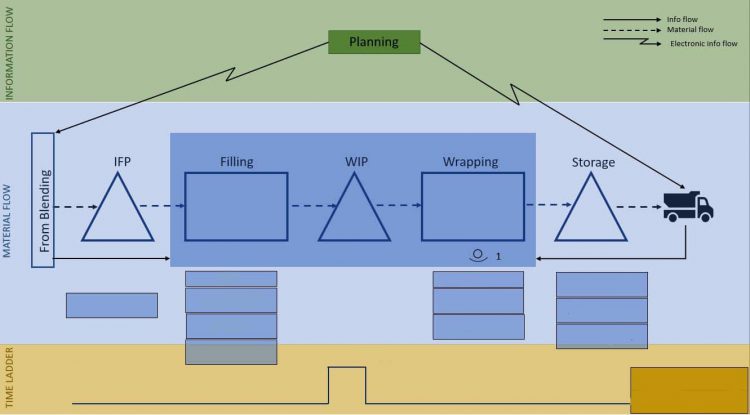

During their 8 weeks presence at the Blending Plant in Antwerp (BPA), Vlerick’s MBA-students Pranav Damodar and Kaushal Trivedi studied the internal process of the filling process for 20 liter pails. The scope of their assignment started just after blending, with the storage of intermediate finished products and ended with the transports leaving from the blending plant, either to the external warehouse or directly to the customer.

Approach of the project

To successfully reach their target, the creation of a current state value stream map of the filling process for 20 liter pails, they used the following steps:

- Meetings with the different departments

- Data collection

- Composition of the current state value stream map

- Identification of the bottlenecks

- Selection of the target area for improvement

- Root cause analysis

Outcome and recommendations

As an outcome of their analysis, Damodar and Trivedi presented a new current state value stream map of the filling process for 20 liter pails, including several recommendations to improve the process.

Their main improvement recommendations were:

- Separating bulk loading from filling would yield a 10% reduction in lead-time in day tanks

- Ensuring packaging material availability can reduce 6% of the lead-time to day tanks

- Avoiding overproduction of 20 liter pails could lead to 3% reduction in lead time

The two MBA-students also proposed the appropriate LEAN-techniques to put these recommendations into practice.

Project closure and appraisal

At the end of June, Damodar and Trivedi presented their report to the project members and the Antwerp management team. The final presentation, as closure of this project, was given at the Vlerick Business School.

We would like to thank Damodar and Trivedi for their good work. Their recommendations are very valuable in the continuous improvement journey of Q8Oils’ Blending Plant Antwerp.

A special thanks to all colleagues who have guided Kaushal and Pranav during the last 8 weeks. Without their help this wasn’t possible!