Until the early 1980s there was no requirement for a group of lubricating oils specifically formulated for gas engines, despite the first commercially viable gas engine having been developed and sold in 1860. These engines were decommissioned after 1900 when gas fuel was superseded by the same type of internal combustion engine fuelled by diesel or petrol.

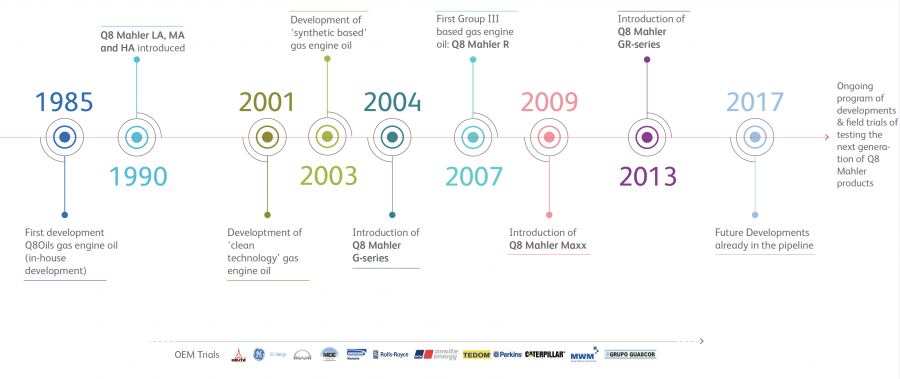

In 1985, Q8Oils set up its in-house research and development departments to investigate its Mahler range of gas engine oils, just as the power generating industry was moving towards the use of natural gas to replace coal as the driver for electricity.

In 1990 Q8Oils launched its first range of oils, Mahler LA, MA, and HA, signifying low, medium, and high ash content. From this beginning, the research and development departments have been led by customer demand, with grades being discontinued, and grades being added, as they were superseded by more advanced performance oils.

The future of gas engine oils

Q8 Mahler Series: always ahead of technological developments

It was another 14 years before Q8Oils released its G range of lubricants, after considerable effort had been put into developing clean engine technology.

The Mahler G range introduced subtle features into the product. Mahler G4 is designed for engines that are sensitive to deposit formation, with 0.4% sulphated ash by mass, and highly effective dispersants. The Mahler G5 is a variant of G4 with a slightly higher TBN and different performance characteristics.

Standard TBN in natural gas engine oils is in the range of 5 to 8 mg KOH/g, but for the alternative gaseous fuels – biogas, landfill gas, sewer gas, sour gas and other polluted gases, Q8 developed Mahler G8 and G10 with higher TBNs. The G8 grade has a TBN of 8 mg KOH/g to counter the high acid levels that are generated during combustion, while G10 offers a high reserve with its TBN of 10 mg KOH/g and is intended for those situations where long drain periods are required.

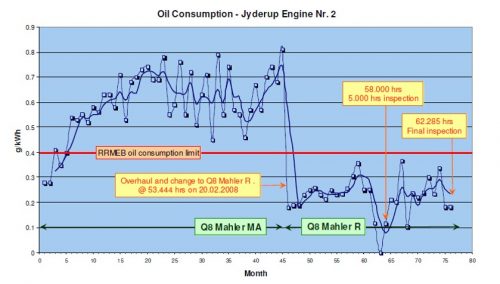

By 2007, Q8Oils was using a Grade III synthetic base oil, making the Mahler Grade R suitable for extreme operating conditions. Even under high temperatures, the oxidation levels are stable, and the oil is able to offer extended drain periods. Two years later Mahler Maxx was released as the oil that exceeded all others in countering the most aggressive and sour gaseous fuels. High in sulphated ash, 1.2% by mass, it has a TBN of 11, it maintains clean engine components, protects against rust and corrosion, and attains high oxidation resistance, thereby enabling long drain periods to be established.

When the GR5 and GR8 grades were introduced in 2013, a major characteristic was the inclusion of optimised viscometrics. This provides the oil with enhanced lubricity that results in improved engine wear protection, excellent fluidity properties at low temperatures, and easier engine starting, especially when the engine is cold.

Building on the performance of the GR grade oils, Q8Oils is working towards the next generation of Mahler products. Throughout Q8Oils research, it will remain focused on achieving:

• Cleaner engines

• Longer oil drain periods

• Lower total operational costs

The work is already showing promising improvements…

1. Reducing the effect that ultraviolet light has on base oils

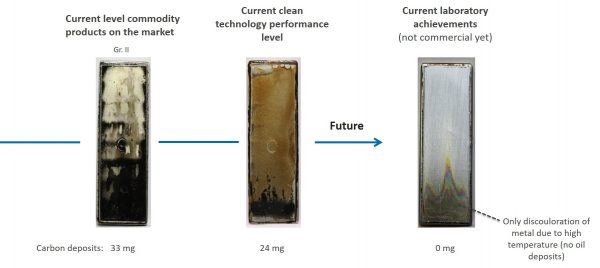

2. Less engine deposits

Further improvements of engine cleanliness

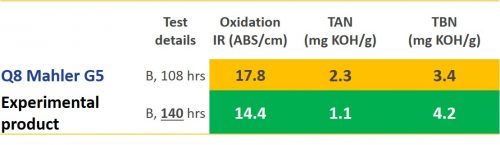

3. Improved thermal and oxidative stability

Significant improvements in:

- Oxidation stability

- Acid value stability

- Base number retention

Test details:

- One cylinder engine

- Operating temperatures 155 °C

- Hotspot 220 °C

4. Lower Oil Consumption

5. Better use of continuous field data for improved insight into performance

6. Better selection of the right product due to performance evaluation testing