When adding a new lubricant to your installation, it is important to know whether this product is compatible with the currently used product. Testing lubricant compatibility goes further than appearance tests. Even more important is to test and maintain lubricant performance.

Before implementing a new product, lubricant end-users and OEMs often question the compatibility of their current product with the suggested product. Especially in cases where the old oil is not changed, but mixed with a new lubricant, the question of compatibility becomes critical to the customer.

What is lubricant (in)compatibility

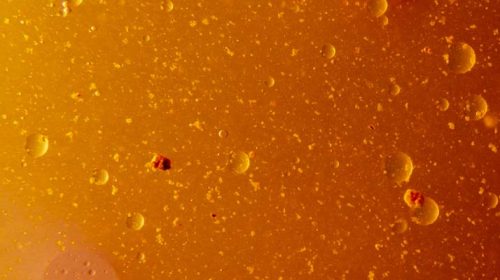

Lubricants are incompatible when differences in base fluids and additive chemistry may lead to undesired chemical reactions. If such lubricants are mixed it can lead to:

- Formation of particles or sludge

- Separate into different layers

- Colour changes

- Loss of solubility of the additive components, resulting in hazy appearance or additive drop-out in the mixture

Lubricant compatibility is no guarantee for performance preservation

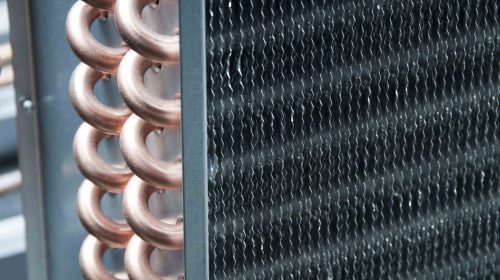

It is also important to clarify that if two products are chemically compatible, the physical properties of the mixture may still be affected. Additive chemistry is based on a careful balance of selected components. When mixing lubricants, this balance may be affected. For example, when two products with different anti-corrosion and anti-wear additives are mixed, the additives compete for the same surface and interfere with each other. While anti-wear performance may improve, the corrosion protection may decrease (and vice versa). This implies that when changing to a better lubricant, the physical properties of the mixture may be affected negatively. Based on laboratory and field experience a significant part (approximately 80%) of the higher performance fluid needs to be present in the mixture to really benefit from the additional performance.

Testing lubricant compatibility

The most common type of compatibility tests are appearance tests. During these tests the mixture is subjected to a series of heating and cooling cycles, before being visually inspected. If the appearance after these temperature cycles is still bright and clear, both products are perceived to be compatible.

Although KPR&T (Kuwait Petroleum Research & Technology) uses a similar approach critical key performance tests are added to the compatibility testing. The reason is that some tests are known to be sensitive to contamination.

With our key performance tests we analyse several lubricant properties, such as:

- Filterability

- Demulsibility

- Air release

- Wear resistance

- Oxidation stability.

We evaluate mixtures of various ratios 20:80, 50:50 and 80:20 and compare them to the test results of fresh oil samples. The products are considered to be compatible if the results in these key performance tests are in the same range as the fresh oils.

Answering your compatibility questions

More and more end-users and OEMs are questioning compatibility between different lubricants. If two lubricants are compatible, the performance properties may still be affected. To answer your compatibility questions, KPR&T has defined compatibility testing which includes both appearance and key performance testing on fresh oils as well as mixtures. This will help to maintain lubricant quality and performance and maintain an efficient and trouble-free operation of your installations.