Lubricants Live Podcast: How Q8Oils is Driving Sustainability in the Industry

The major challenges for gas and steam turbine oils is viscosity, oxidation and thermal stability. The Q8 Volta high performance turbine oils are based on Group III base fluids, delivering excellent wear protection and oxidation stability. These products have received an impressive list of OEM approvals and are first choice for many gas and steam turbines owners.

Until the early 1980s there was no requirement for a group of lubricating oils specifically formulated for gas engines, despite the first commercially viable gas engine having been developed and sold in 1860. A lot has changed since then, and with the Q8 Mahler range, Q8Oils is ready for the future.

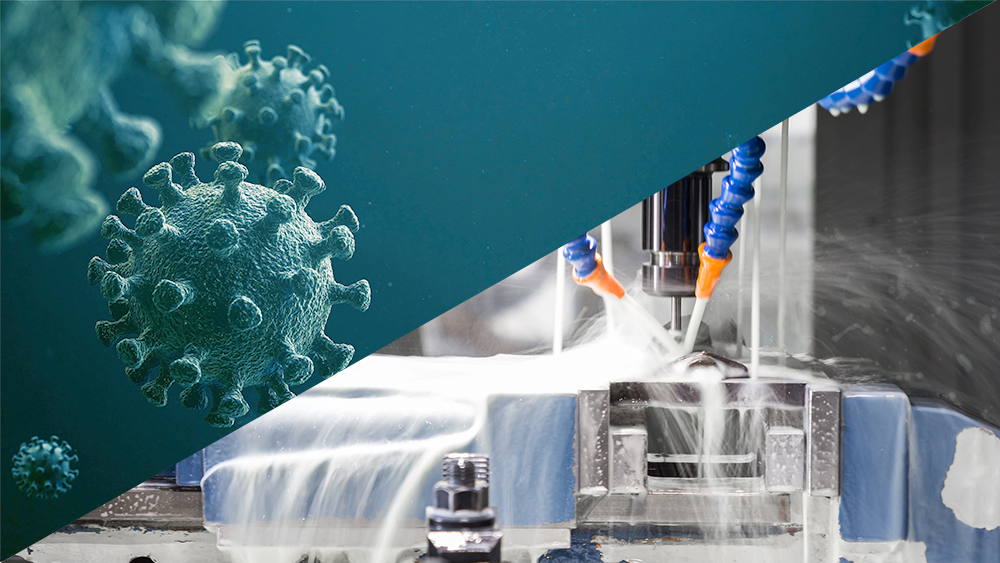

If you’re stopping or scaling down production during the coronavirus crisis, here are some tips on how to manage your metalworking fluids and protect your machinery to make sure that you’re ready to restart quickly and trouble free.

Avoiding oil contamination is crucial for the performance and long-life of your machine. Preventing contaminants from entering the fluid system is an impart part of any contamination control strategy. This article explains the three most common ways contaminants can enter your fluid system.

In the stationary gas engine industry there are many ‘urban legends’ and ‘rules of thumb’ about lubricants.

Nitration is an undesirable degradation of engine oil that occurs in a reduced oxygen environment. It causes deposit forming and can eventually result in reduced engine performance and damaged engine parts. Discover how to detect, avoid and solve nitration in your gas engine.