The increasingly stringent emission regulations and fuel-economy demands have forced engine manufacturers to downsize engines while improving their power and torque. The downside of today’s smaller engines with higher power density is their risk to abnormal disruptive combustion, such as knocking and a new phenomenon called low speed pre-ignition (LSPI).

In the race to produce the most fuel-efficient engine, Original Equipment Manufacturers (OEMs) are producing direct-injected (DI) gasoline engines that keep getting smaller. These type of engines achieve significant efficiency and fuel-economy benefits compared to a conventional, larger engine of the same power.

The downside of smaller DI engines

Most smaller engines today are equipped with turbochargers, variable valve timing and/or direct-fuel injection to combine high power and torque with improved fuel economy. Unfortunately, these benefits also come with some significant risks. Turbocharged, direct-injected gasoline engines have an undesired tendency toward pre-ignition or spontaneous combustion early in the combustion cycle. The phenomenon is called low speed pre-ignition (LSPI) and occurs especially at lower speed and high torque conditions.

Wat causes LSPI?

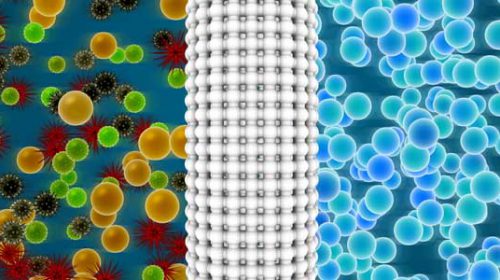

There are several theories explaining the mechanism of LSPI. The initial explanation located the sources of pre-ignition at certain hot spots on the surface of the cylinder. However, further research revealed that pre-ignition arises at random places across the combustion chamber. The latest assumption is that an oil droplet enters the combustion chamber from a crevice between the piston and cylinder wall. When this oil droplet mixes with the fuel and air mixture, it causes a premature ignition that clashes with the upward moving piston.

What is the risk of LSPI?

The pre-ignition, audible as a heavy knock, causes a heavy force on the piston. It can lead to engine defects in just a few engine cycles. Ongoing LSPI can lead to severe damages such as bent connecting rods, damaged ring lands and broken piston rings.

How to prevent LSPI?

To prevent LSPI from happening you need to understand the factors that influence the undesired pre-ignition. Studies have shown that engine design, fuel composition and lubricant composition are the most important impact factors.

Tests show that lubricants with a higher calcium concentration increase the risk of LSPI, while magnesium-based products do not seem to provoke LSPI. You might think that reducing the calcium concentration in engine oils is the most straight-forward solution. However, this causes other disadvantages on engine life, performance and efficiency.

Specialized lubricants to avoid LSPI

By accumulating the right additives and base oil you can develop an oil formulation that successfully reduces the risk of LSPI. Next to the mixture of detergents, the quality of the base oil influences the occurrence of LSPI in the combustion chamber.

Q8Oils’ research and development team continues its efforts to optimize their engine oils for robust LSPI performance, while maintaining the right level of detergency to keep engine parts clean, neutralize acids and extend engine life.

As a solution we are able to offer our Q8 Formula Special D1 5W-30 and Q8 Formula Elite C2 EVO, specially designed to solve the LSPI challenge in GM/Opel engines, based on Dexos1 Gen2 technology.