Particle count is a proven test method to determine the contamination ratio of lubricants. It helps to avoid machine failure and high maintenance costs. Want to know more? Read the article.

Particle count: n°1 method for oil cleanliness analysis

Particle count is a proven test method to determine the contamination ratio of lubricants. It helps to avoid machine failure and high maintenance costs. Want to know more? Read the article.

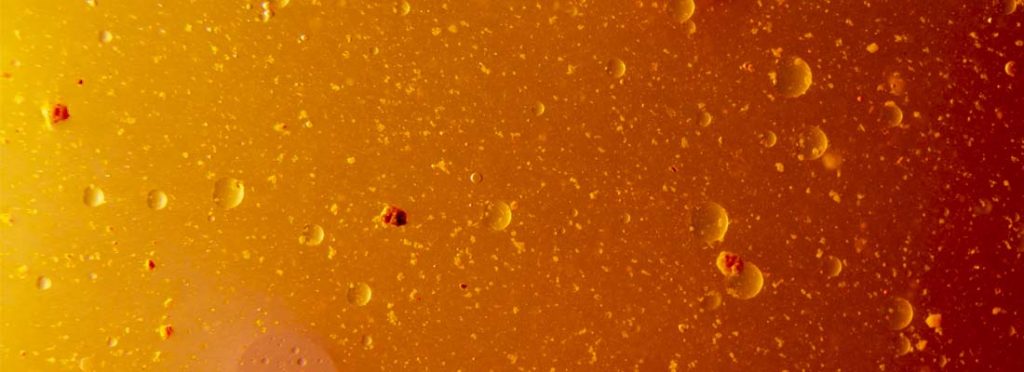

Where the refrigerant is essential for the cooling properties of a refrigeration system, the refrigeration oil is crucial for the correct functioning of the compressor. Lubricants for refrigeration compressors reduce friction, prevent wear and act as a seal between the high and low pressure sides. But how do you select the best refrigeration oil?

Q8Oils has strategically partnered with Northeast-Western Energy Systems (“NES-WES”), which is, as of now, the strategic distribution partner in the US. The mutual goal of both companies is to provide the longest lasting oil life at the most cost-effective price, significantly reducing overall lubricating oil costs.

Following the partnership with Q8Oils, NES-WES can now offer a complete comprehensive fluids package to customers which includes lube oil, gear box oil and coolant.

Oxidation rating is one of the elements that influence oil drain interval. In this article we describe the different methods to test the oxidation rating of used gas engine oil samples.

When adding a new lubricant to your installation, it is important to know whether this product is compatible with the currently used product. Testing lubricant compatibility goes further than appearance tests. Even more important is to test and maintain lubricant performance.

Primato grows tomatoes on a total surface of 125.000 m2. For the powering and heating of their greenhouses, they use a combined heat and power (CHP) installation, driven by INNIO Jenbacher 624 engines. The newly developed Q8 Mahler GR8 was successfully tested in this challenging application and resulted in longer drain intervals, higher efficiency and cleaner engine parts.

Engine applications with landfill gasses are the biggest challenge for every oil manufacturer. The specific conditions of these engines push the desired quality and performance of oils to the limits.

Q8 Sinan is the latest addition to Q8Oils’outstanding range of specialty compressor lubricants. The Q8 Sinan is a specially designed high-performance synthetic lubricant based upon polyalkylene glycol (PAG) technology and has been developed for hydrocarbon and chemical gas processing compressors.