In the stationary gas engine industry there are many ‘urban legends’ and ‘rules of thumb’ about lubricants.

Whitepaper: Urban legends about gas engine oils

In the stationary gas engine industry there are many ‘urban legends’ and ‘rules of thumb’ about lubricants.

Nitration is an undesirable degradation of engine oil that occurs in a reduced oxygen environment. It causes deposit forming and can eventually result in reduced engine performance and damaged engine parts. Discover how to detect, avoid and solve nitration in your gas engine.

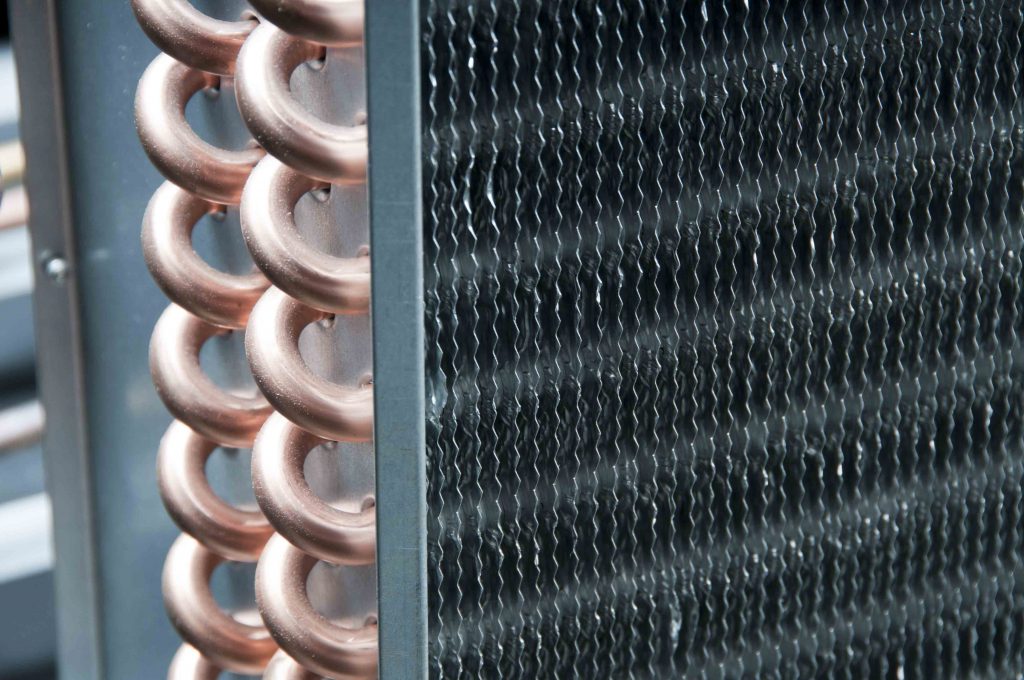

Where the refrigerant is essential for the cooling properties of a refrigeration system, the refrigeration oil is crucial for the correct functioning of the compressor. Lubricants for refrigeration compressors reduce friction, prevent wear and act as a seal between the high and low pressure sides. But how do you select the best refrigeration oil?

Q8Oils will present their new high ash gas engine oil during the international UNITI Mineral Oil Technology Congress. The new Q8 Mahler GR8 offers major improvements in engine cleanliness as well as drain interval. It challenges the guideline of low ash gas engine oils and reduces operational costs of stationary gas engines.

Q8Oils has strategically partnered with Northeast-Western Energy Systems (“NES-WES”), which is, as of now, the strategic distribution partner in the US. The mutual goal of both companies is to provide the longest lasting oil life at the most cost-effective price, significantly reducing overall lubricating oil costs.

Following the partnership with Q8Oils, NES-WES can now offer a complete comprehensive fluids package to customers which includes lube oil, gear box oil and coolant.

Q8 Volta EP is a high-performance gas and steam turbine oil, based on Group III base fluid. The oil was specially developed for its excellent oxidation stability and wear protection as the oil is in use.

For more than 30 years Q8Oils has been performing research to answer the typical challenges of gas engine oils. The result is a range of products that prolong the drain interval and engine cleanliness and to increase the life span of cylinder heads, specifically the valves and the vale seats.

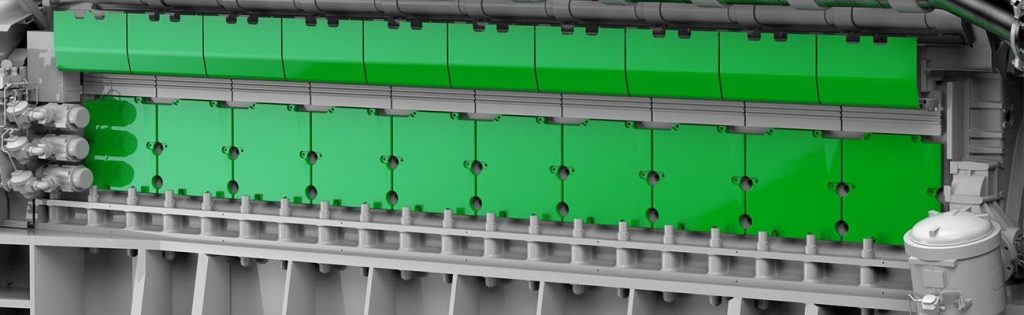

INNIO Jenbacher approved Q8 Mahler GR8 as the first high performance 0.8% S-Ash gas engine oil for the use in INNIO Jenbacher 9-series gas engines. The approval is the result of a series of field trials and in-house tests.

Oxidation rating is one of the elements that influence oil drain interval. In this article we describe the different methods to test the oxidation rating of used gas engine oil samples.

The main circulation lubricant in industrial applications comes into contact with anti-rust fluids and sealants used to prevent leakages. Q8Oils has tested and analysed how these products affect lubricant anti-wear properties.

In order to understand what could happen if the system is not properly flushed before start-up and if excessive amounts of sealant are used, Q8Research has investigated this issue.