From then to now: the benefits of metalworking fluids

Q8Oils is pleased to have made an important contribution to a new guide on good practice for the safe handling of metalworking fluids in the workplace.

Forced by new regulations lubricants manufacturers worldwide are replacing the mineral base oils in metalworking fluids by natural sourced derivatives.

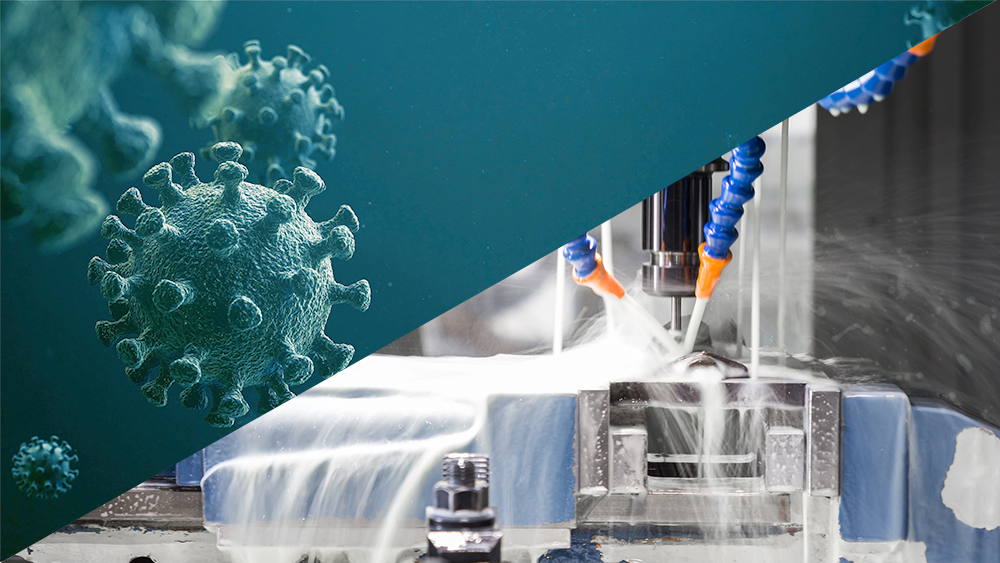

Q8Oils is proud to be a supplier to Cambridge Precision Ltd – one of the many amazing manufacturers who are pulling out all the stops in the fight against Covid-19.

If you’re stopping or scaling down production during the coronavirus crisis, here are some tips on how to manage your metalworking fluids and protect your machinery to make sure that you’re ready to restart quickly and trouble free.

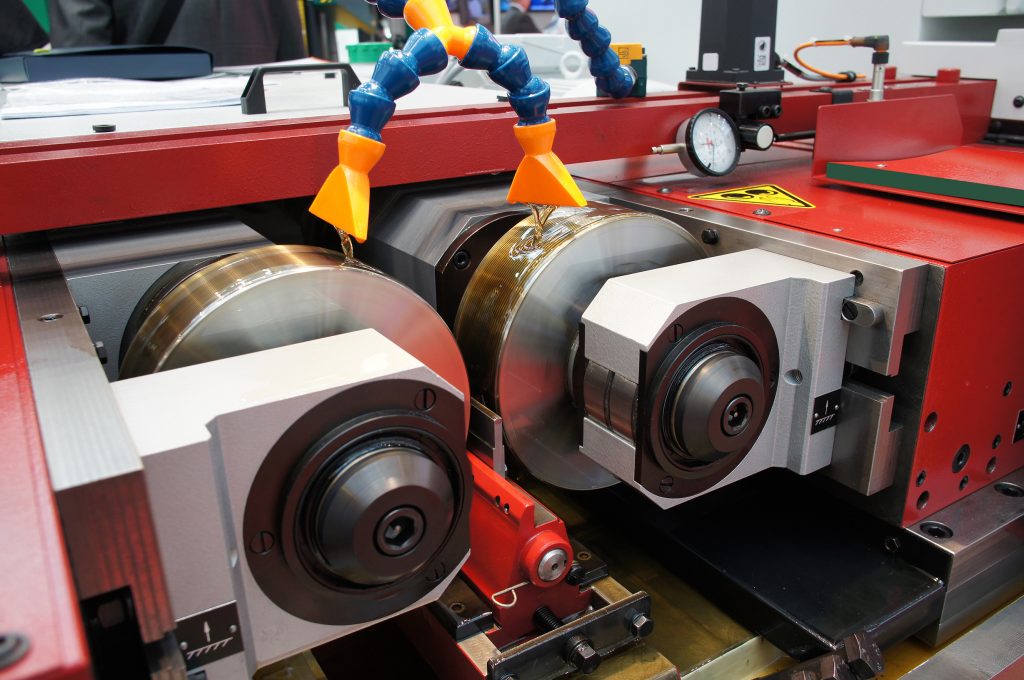

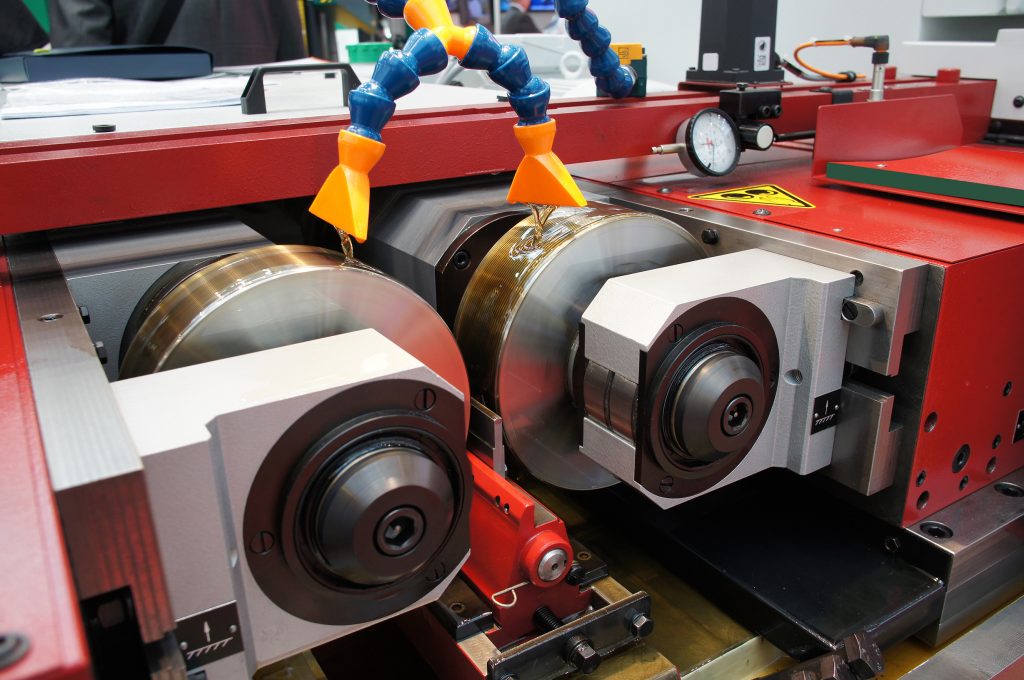

Visit Q8Oils at stand 11 B16 at Wire & Tube 2020 to discuss its many products and service-led initiatives available for the worldwide wire, tube and cable market.

Q8Oils has launched its most advanced range of cutting oils – Q8 Bach 7000 – which break the boundaries in performance and safety.

In August, Q8Oils visited Freddy Products Ltd, the manufacturer of the highly regarded and world-renowned Freddy range of coolant and swarf recycling vacuums.

Q8Oils is a key player in the metalworking industry and develops a wide product range of metalworking fluids, allowing our customers to choose the perfect solution for their process and application. Our strategic pillar of metalworking fluids increases the profitability and sustainability of big and small companies worldwide.

At Q8Oils, the answer is quite a lot! We have produced a paper to give you the key facts about aluminium, from its properties and classification to important considerations in the machining process.