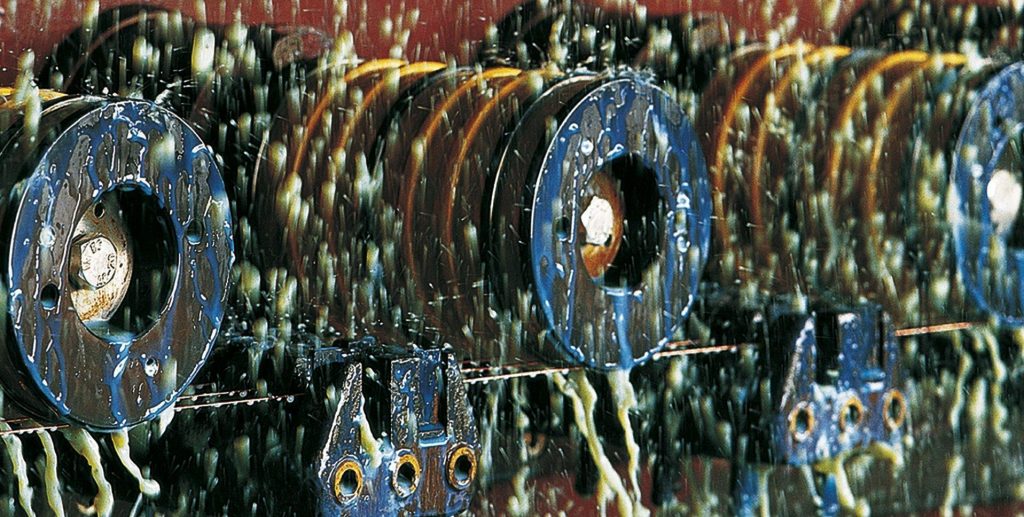

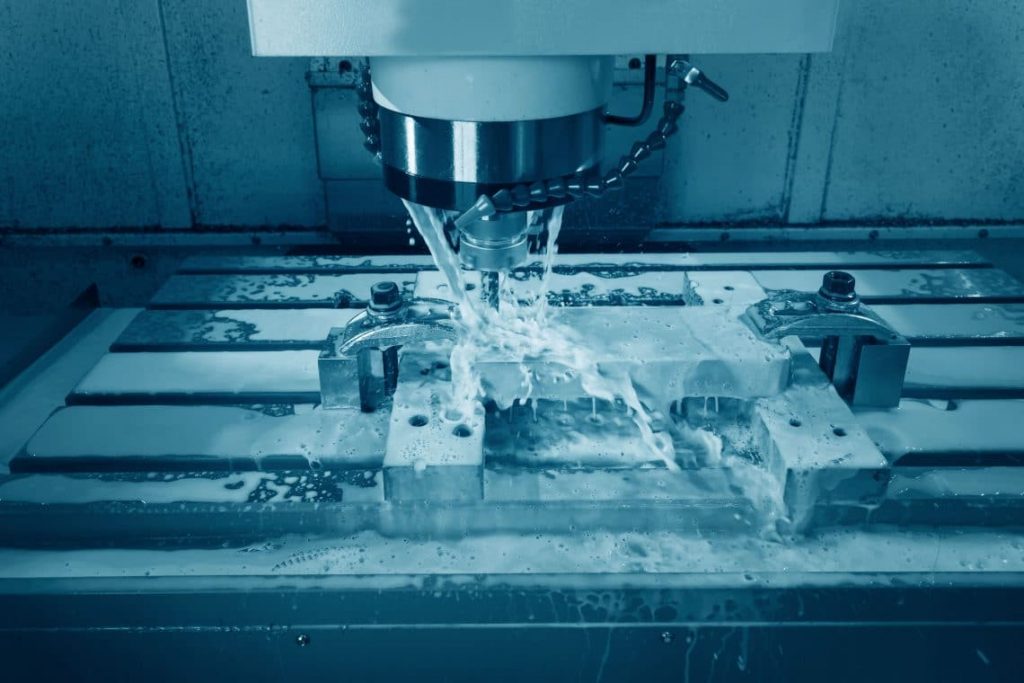

Getting the most from your metalworking fluid is all about choosing the correct equipment. Using the right equipment makes it possible for you to enhance the life of your fluid, improve its longevity and prevent problems in the future. So, what equipment should you use?

8 pieces of equipment you should have when using metalworking fluids