Visit Q8Oils at stand 11 B16 at Wire & Tube 2020 to discuss its many products and service-led initiatives available for the worldwide wire, tube and cable market.

Q8Oils at Wire & Tube 2020

Visit Q8Oils at stand 11 B16 at Wire & Tube 2020 to discuss its many products and service-led initiatives available for the worldwide wire, tube and cable market.

Getting the most from your metalworking fluid is all about choosing the correct equipment. Using the right equipment makes it possible for you to enhance the life of your fluid, improve its longevity and prevent problems in the future. So, what equipment should you use?

European technology and expertise tailored for the Worldwide Industry. Technical support to improve the productivity of the lubricant in your applicationWorldwide supply and support, exports to customers in over 85 countries. Seeking distributors and agents with technical expertise.

In the wire drawing industry, the terms superfine and ultrafine are commonly used to describe sizes of fine wire, but how do you describe it in your wire drawing application, how also does wire size relate to life and what you can see?

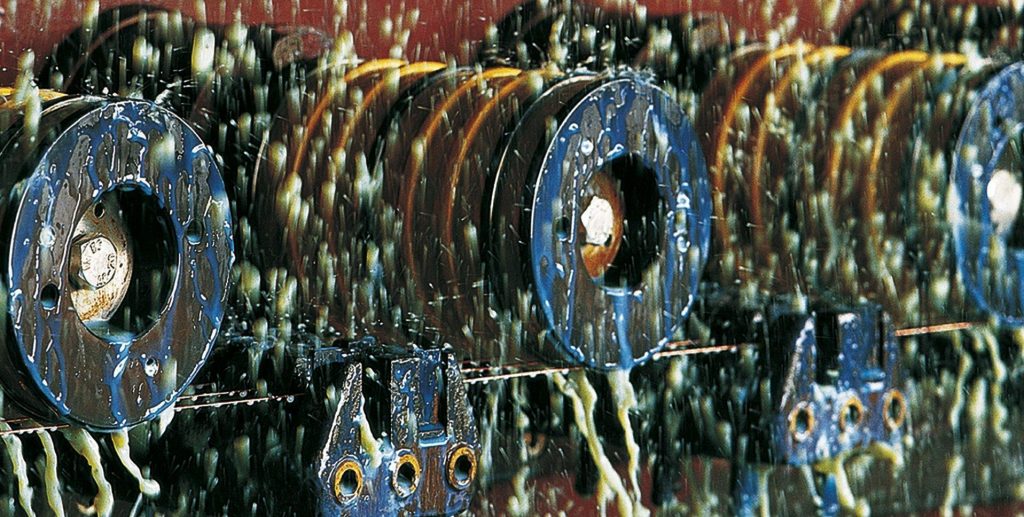

Q8Oils’ drawing solutions are the result of more than 100 years of product development and application experience.

The aluminum wire drawing emulsion as like copper should be filtered effectively, this promotes clean running by removal of abrasive and reactive fines from the system. In aluminum emulsions it is best to use two systems, a centrifuge and also a paper filtration. A third system of a vacuum filtration could also be considered to remove the lightweight particles.

The use of soluble oil emulsions for aluminium drawing is not a new application, however with newer types of additive and the performance that they provide, substantial benefits can be provided to the drawing company by using emulsions over drawing oils. Emulsions can be used for both EC and Alloys across all wire sizes from rod to super fine applications.

Lubrication consistency with newer generation copper wiredrawing lubricants can be demonstrated and proven with both laboratory analyses and in live factory applications. Under controlled identical conditions, product technologies can be cross-referenced and compared in KPI’s laboratories.

The technical service and support for aluminum drawing oils to determine the overall condition and suitability for continued use, are routinely as follows.

Today’s global working environment poses economic challenges for manufacturers, making increased factory productivity a key for successful growth. That makes it important for companies to be able to measure productivity and understand what aspects are important to increase it.