The energy sector is very demanding when it comes to the performance of lubricants for stationery gas engines. Thanks to its wide-ranging experience in this challenging sector and its innovative R&D program, Q8Oils produces the best-in-class gas engine oils with the best performance and longest drain intervals on the market.

Focussing on engine type characteristics

Every engine type has its own specifications and requirements. By focussing on these specific characteristics Q8Oils is able to develop and manufacture products that are tailor-made for every different engine type. No wonder the Q8Oils product range for the energy sector is by far the most extensive on the market.

Gas engines in particular are subjected to extreme operating conditions, especially around the combustion chamber. This results in significant challenges in terms of oxidation and deposit control and Total Base Number (TBN) retention. The ‘clean technology’ of the Q8 Mahler G- and GR-series is the perfect answer. These oils offer outstanding benefits:

- high oxidation and nitration resistance for long service life

- low ash deposit tendency and good resistance against pre-ignition

- excellent anti-wear properties protecting the engine against valve seat recession

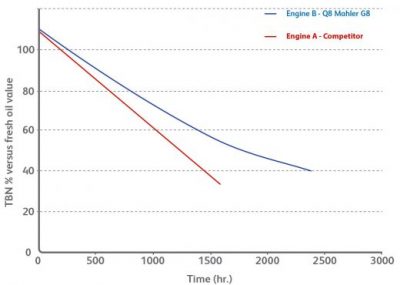

- high TBN retention enabling high acid neutralising capacities

Comparative tests with biogas engines

To proof the Q8 gas engine oils deliver the best performances, we did some comparative tests between the Q8 Mahler products and other OEM approved A-brand competitors. The results speak for themselves.

Test 1: problem free operations and extended drain interval

For the first test we went to a big company that produces biogas. Subject of our test was a INNIO Jenbacher J 320 gas engine. The requirements of the customer were as clear as they were challenging:

- Problem-free operations

- Extended drain interval

- Low deposit tendency

Using traditional stationary gas engine oils in the past, the customer noticed a clear correlation between ash-content and deposit tendency. This is different with the ‘clean technology’ Q8 Mahler G8 that controls the deposits better than most traditional oils. The additional detergent capacity of Q8 Mahler G8 increased the drain interval by 25 %. Together with continuous problem-free operations all customer’s demands were met.

Test 2: extended drain interval and increase in filter lifetime

Our subject for the second test was found in Denmark: a INNIO Jenbacher 620 F with steel pistons. The customer’s requirements were similar as in the first case:

- Extended drain interval

- Low deposit tendency

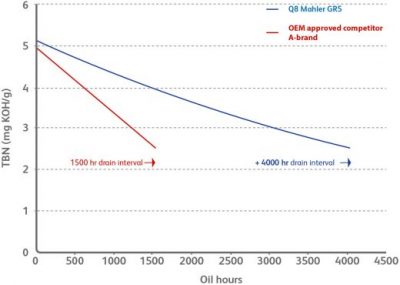

- Clean engine

In this case the steel pistons asked for an oil that is specifically developed to deliver a high oxidation stability and the ability to control piston/liner cleanliness at increased piston ring temperatures. The Q8 Mahler GR5, a high performance gas engine oil based on group III base oil, proved to be the perfect fit. The engine achieved more than 4.000 hours oil life without filter changes. Its competitor achieved only 1.500 hours oil life with filter changes every 500 hours.

By using the Q8 Mahler GR5 engine oil the customer extended the drain interval with a stunning 150 %, while the filter life time increased with 200 %. The customer was happy with the results: a reduction of maintenance costs and an increase of operations efficiency.