Particle count is a proven test method for industrial oil analysis. It helps you determine the contamination ratio of the oil in your processes, thus helping you to avoid machine failure and unexpected downtime.

Studies have shown that over 70% of the equipment failures in circulating systems are caused by particulate contamination of the oil. Hence, the importance of clean oil cannot be overstated. But how can you measure the contamination ratio of your used oil? And when do you know when it is time for new oil? The answer to both questions is: particle count!

What is particle count?

Particle count is a proven test method for industrial oil analysis. The principle is simple: by measuring the number of particles in used oil, you know the contamination ratio of the oil. That way, it helps you to determine whether the oil is clean enough for reliable operation.

By monitoring the number and size of particles in an oil sample, you can quickly determine a multitude of problems.

Why use particle count?

Visual inspections of oil samples are not sufficient to obtain a complete and correct image of the degree of oil contamination. Even particles which are far too small to see, can cause serious damage. Your oil might look clean for the naked eye, yet it could still cause abrasive wear, reducing equipment performance and system efficiency.

Methodical and standardized particle count gives you a good insight in the degree of cleanliness and the condition of the machine and the lubricant itself.

How to measure particle count?

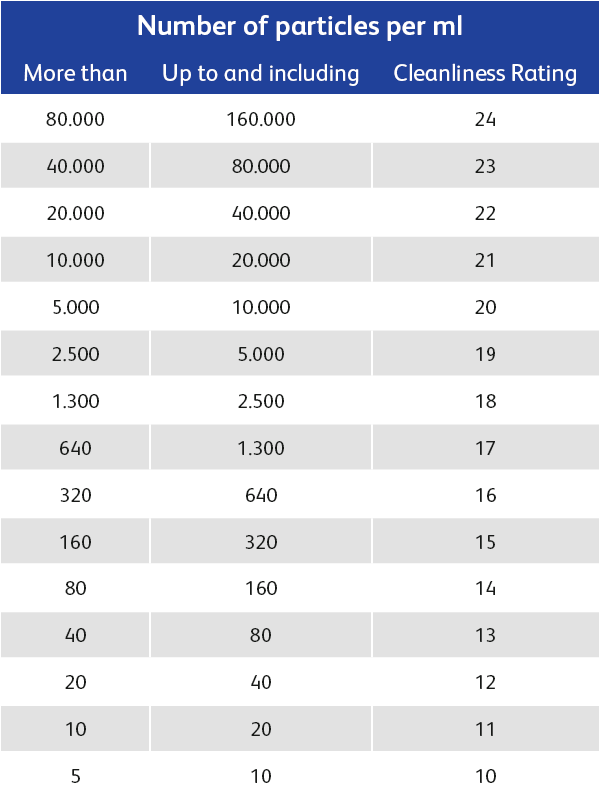

When using particle count, it is important to deploy it in a standardized way. ISO has published the industry standard ISO 4406, also known as the ISO cleanliness code. It specifies the code to be used in defining the number of particles in a lubricant.

This standard determines the number of particles in three different size categories:

- >4µm

- >6µm

- >14µm

The number of particles of each size category is converted to an ISO code, or Cleanliness Rating, as shown in the table below.

Standardized method for particle count

ISO 4406:99 is the most common method to report the cleanliness of an oil sample, yet it is not the only one. Other standards include NAS 1638 and MIL-STD 1246C and the outdated SAE fluid cleanliness rating system.

Whichever cleanliness reporting method is used, you should always start with counting the quantity of particles in a volume of fluid.

The advantages of particle counting

Particle count offers a lot of benefits in a multitude of applications, such as:

- Determining oil cleanliness

- Filter performance analysis

- Confirmation of corrective maintenance

- Pump condition verification

- Cleanliness verification of stored lubricating fluids

- Determining the optimal timing for filter replacement

- Checking new filter abnormalities

- Identification of abrasive wear conditions

- Checking whether target cleanliness levels are achieved

Need help with particle count?

Q8Oils produces high-performing lubricants which minimize the formation of oil particles and avoid machine wear. Q8 Routine Analysis Service (better known as QRAS) is our added value service that helps you with meticulous oil sample analysis and advice. Thanks to our analyses, such as standardized particle count methods, you can reduce your operating costs and optimize your lubrication program.

Regularly performed oil analyzes help prevent serious damage or malfunctions by indicating which measures are needed and how urgent they are.