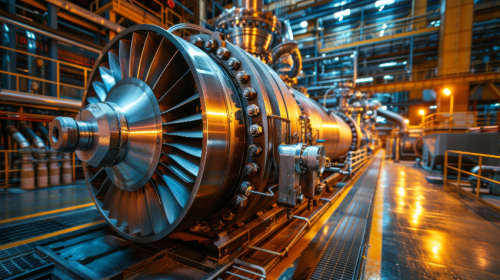

Gas engines are subjected to extreme operating conditions, speeding up the deposit formation process in the oil and thus posing high engine wear risks. The Q8 Mahler is especially developed to perform in these harsh circumstances. Also for the Sagunto Water Treatment Plant in Valencia (Spain), Q8 Mahler G10 proved to deliver high-class wear protection and TBN retention for this extreme gas engine application.

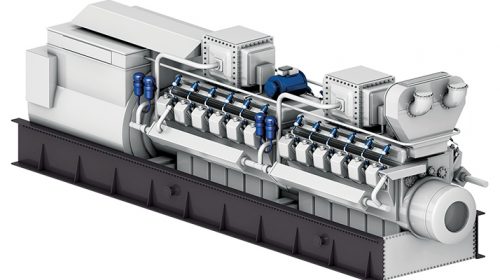

The Sagunto Water Treatment Plant (WTP) is equipped with a INNIO Jenbacher 230 GS-B.L. biogas engine from the year 2002. In January 2015 Sagunto WTP contacted Q8Oils to help selecting the best oil for this old engine. The first QRAS* analysis after 250 oil service hours revealed two important deficiencies:

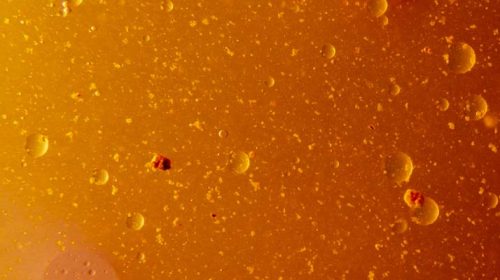

- High presence of wear metals such as iron and copper.

- Poor TBN retention due to high aggressive compounds concentration (such as hydrogen sulphide) in the biogas.

In consultation with the Q8Oils experts, Q8 Mahler HA was chosen to lubricate the INNIO Jenbacher engine.

*QRAS (Q8 Routine Analysis Service) is an added value service that helps engine owners to lengthen machine life and reduce costs. Discover more about QRAS.

Q8 Mahler G8: improved TBN and iPH retention

One year later the Sagunto WTP contacted Q8Oils again to find a solution to reduce the amount of wear metals and increase the TBN and iPH retention. After further oil performance analysis, Q8Oils recommended to upgrade to Q8 Mahler G8, with immediate improvements on TBN and iPH retention. However, the analysis showed copper levels that were completely out of range, indicating a potential mechanical and thus not oil related problem in the engine. When disassembling the engine, a broken connecting rod was discovered. After replacement and reassembly the engine started running again.

Q8 Mahler G10: wear metal reduction extends engine service life

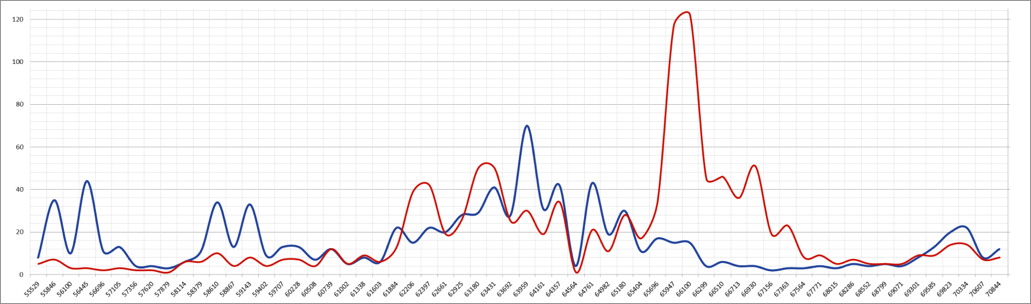

The customer kept looking to improve the oil performance. Although a third party recommended to add an additive to the Q8 Mahler G8, the customer remained its confidence in Q8Oils. After a deep study conducted by Q8Oils Energy Team, the final recommendation was switching to Q8 Mahler G10. This decision was an immediate success. The first Q8 Mahler G10 analysis showed outstanding results that were confirmed by the last analysis in December 2017:

- Excellent TBN and iPH retention.

- Substantial wear metal levels reduction (below the upper limits for both copper and iron).

For the Sagunto WTP the Q8 Mahler G10 proved to be the best oil choice to protect the engine and extend the service life as much as possible. The chief of maintenance at the Sagunto WTP was clear:

“When we received the QRAS analysis results after the switch to Q8 Mahler G10, our first thought was that there had to be something wrong. It was unbelievable. We are really happy with the Q8Oils and Q8 Mahler G10 performance in our gas engine.”

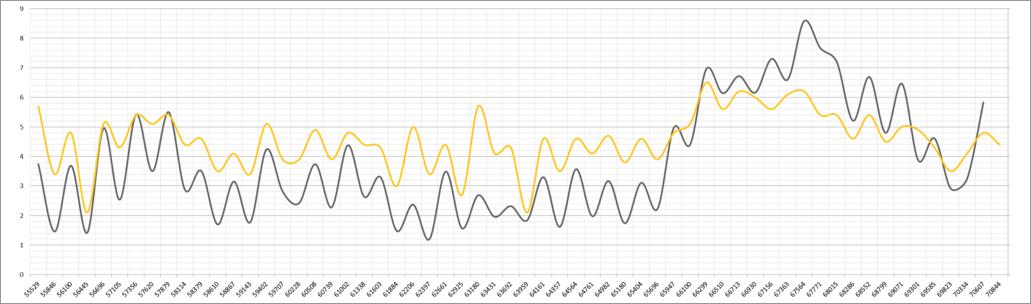

Oil performance analysis charts

The vertical lines in the following charts represents the switch moment from Q8 Mahler HA to Q8 Mahler G8 and then to Q8 Mahler G10.

Conclusion

Thanks to the Q8 Mahler engine oils the Sagunto WTP INNIO Jenbacher engine has been running for 15.000 hours with only standard preventive maintenance, meaning no corrective maintenance was needed. Q8 Mahler G10 assures top class performance for extreme gas engine applications, where outstanding wear protection and TBN retention are needed.

The customer will no longer maintain the engine, so it will keep running until it collapses. Thanks to Q8Oils’ high-performing product range and added-value services with excellent results, the customer will keep Q8Oils as the partner of choice when they replace the old engine for a brand new one.