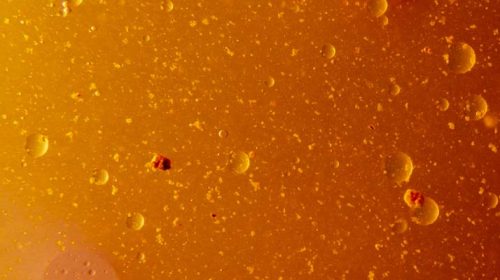

Engine applications with landfill gasses are the biggest challenge for every oil manufacturer. The specific conditions of these engines push the desired quality and performance of oils to the limits. To stabilize the high concentration of acids, oil with a higher ash content is required. The numerous reactions of overbased detergent and acids leads to an increased formation of deposits and a bigger risk of undesired liner lacquering.

Cleaner engine with reduced oil consumption

Specifically for these harsh environments Q8Oils has developed the Q8 Mahler G8 engine oil. Thanks to its unique technology the deposits are kept in the oil, avoiding lacquering and limiting oil consumption.

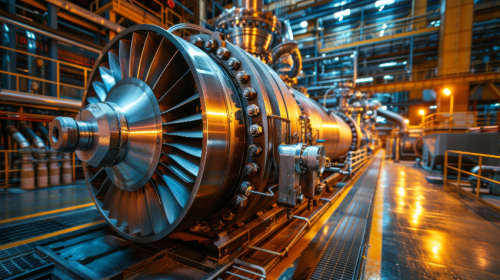

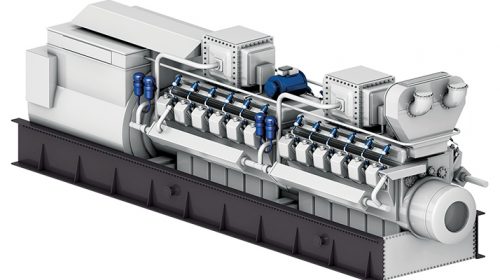

In New Zealand we performed a comparative test between the Q8 Mahler G8 engine oil and an OEM approved A-brand competitor. The subject of research: a INNIO Jenbacher 320GS gas engine. The customer tried Q8 Mahler G8 for 7.000 consecutive hours at their landfill site and compared the results with their traditional A-brand engine oil. The results were stunning:

- Oil drain interval increased with 200 hours.

- Oil consumption reduced with 40 %.

- Inspections indicated fewer deposits and an improved engine cleanliness.

- Deposits were extremely soft compared to those formed by the competitor gas engine oil.

- Where the liners used to be covered from base to top due to lacquering, with the Q8 Mahler G8 lacquering only appeared slightly on the upper ends of the liners.

Minimize operating costs and achieve the best productivity

The Q8 Mahler- range of high quality lubricants for gas engines has proved its outstanding anti-wear properties and high acid neutralising capacities over the years.

Customers testify:

“By using the Q8 Mahler engine oils we achieved a longer than expected oil life accompanied by reduced combustion chamber deposits and minimal liner lacquering, resulting in extended liner and cylinder head life. As with all engines running on landfill gas, these benefits are of great importance for both the smooth running and reduction in operating costs.”

Operating conditions vary substantially and Q8Oils can provide advice on the best oil for your application. You can also benefit from Q8Oils’ Analysis Programme to help you achieve the best productivity and reliability.