Nitration is an undesirable degradation of engine oil that occurs in a reduced oxygen environment. It causes deposit forming and can eventually result in reduced engine performance and damaged engine parts. Discover how to detect, avoid and solve nitration in your gas engine.

Nitration is a form of oil degradation in stationary gas engines that is caused by a reaction of the oil with gaseous NOx created during combustion.

How nitration in gas engines occurs

High temperatures in gas engine operation can cause atmospheric nitrogen (N2) and oxygen (O2) to react, forming nitrous oxides (NOx). Nitration occurs when the oil is becoming saturated with soluble and/or insoluble nitrogen-oxide compounds.

As the base oil reacts with nitrogen, two types of nitrogen compounds are formed:

- Organic nitrates: While the engine is running, oil lubricates the cylinder wall and is removed by the oil scraper ring. These components reach the crankcase where they form sludge and varnish. When the saturation point is reached, they drop out, forming organic nitrates.

- Nitro compounds: The formation of these components is caused by piston blow-by, exhaust gas leaking into the oil, leaking turbocharging seals, lack of oil, …

How to detect and solve the source of nitration in gas engine oils?

It is important to detect and solve nitration in an early stage to avoid performance loss or engine damage.

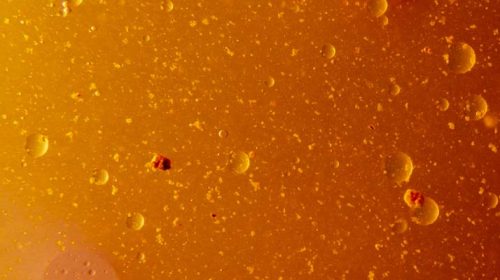

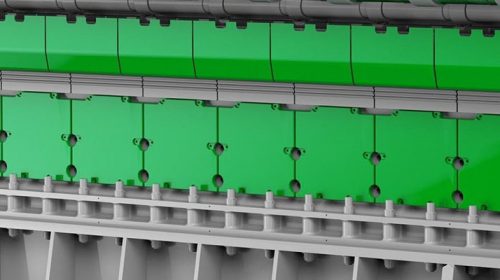

Visual inspections of the rocker arm and valve assembly area and the piston skirt of an engine are an easy way to detect nitration. If you detect amber-to-maroon-coloured deposits, you probably have to deal with nitration.

Apparent changes in performance indicators such as abnormal oil consumption, engine performance reduction or shorter filter life could also indicate possible nitration issues.

Factors influencing nitration in gas engine oils

There are many possible causes of nitration in gas engine oils. Consider the following factors to detect and avoid nitration:

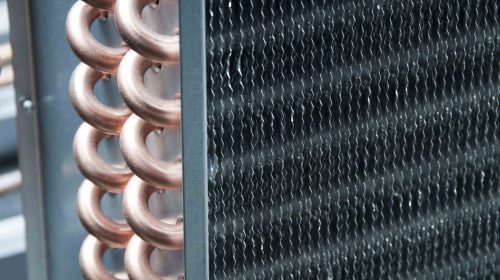

- Crankcase ventilation: By improving the ventilation of the crankcase, you avoid contact between NOx and the oil.

- Cylinder wall temperature: Organic nitrates are mainly formed on the oil layer on the cylinder wall. Nitration typically occurs at lower cylinder wall temperatures.

- Piston ring sealing: Poor piston ring sealings causes blow-by of combustion gas into the crankcase. This increases the formation of nitro compounds.

- Oil sump temperature: Blow-by gases that enter the sump can cause the reaction between NOx and the oil. The chance of nitration increases at lower oil sump temperatures.

- Base oil type: Base oils with saturated hydrocarbon structures, such as hydrotreated Group II base oils (like Q8 Mahler G series and hydrocracked Group III base oils (like Q8 Mahler GR series), are less prone to nitration.

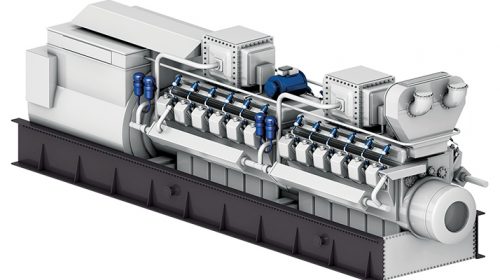

How Q8Oils avoids nitration issues in your gas engine

The best way to protect your gas engine against the effects of nitration is by regularly performing an oil analysis.

At Q8Oils we have developed the Q8 Routine Analysis Service (QRAS) to help you achieve the best productivity and reliability.

Another way to avoid nitration issues is by performing regular maintenance and accurate inspections of your gas engine. With our endoscope service we use optical instruments to inspect most elements of your gas engines, without downtime. The results allow for the early identification of any damage or malfunctions.

Using the right gas engine oil is key to avoid nitration. The Q8 Mahler gas engine oils are based on Group II and Group III base oils which offer a good natural resistance against nitration. The clean technology chemistry of Q8 Mahler reduces the negative impact of nitration, for example by preventing the increase of acidity.