In the world of engineering, manufacturing turned and milled components is a very precise one. A leading company in this field is Ypsotec, a Czech-based firm renowned for its expertise and innovation.

Q8 Brunel XF 741 was introduced to Ypsotec through a trusted partner of Q8Oils in the Czech Republic, Libor Hromádka of LH Services, who has been representing Q8Oils excellently since 2022.

Ypsotec

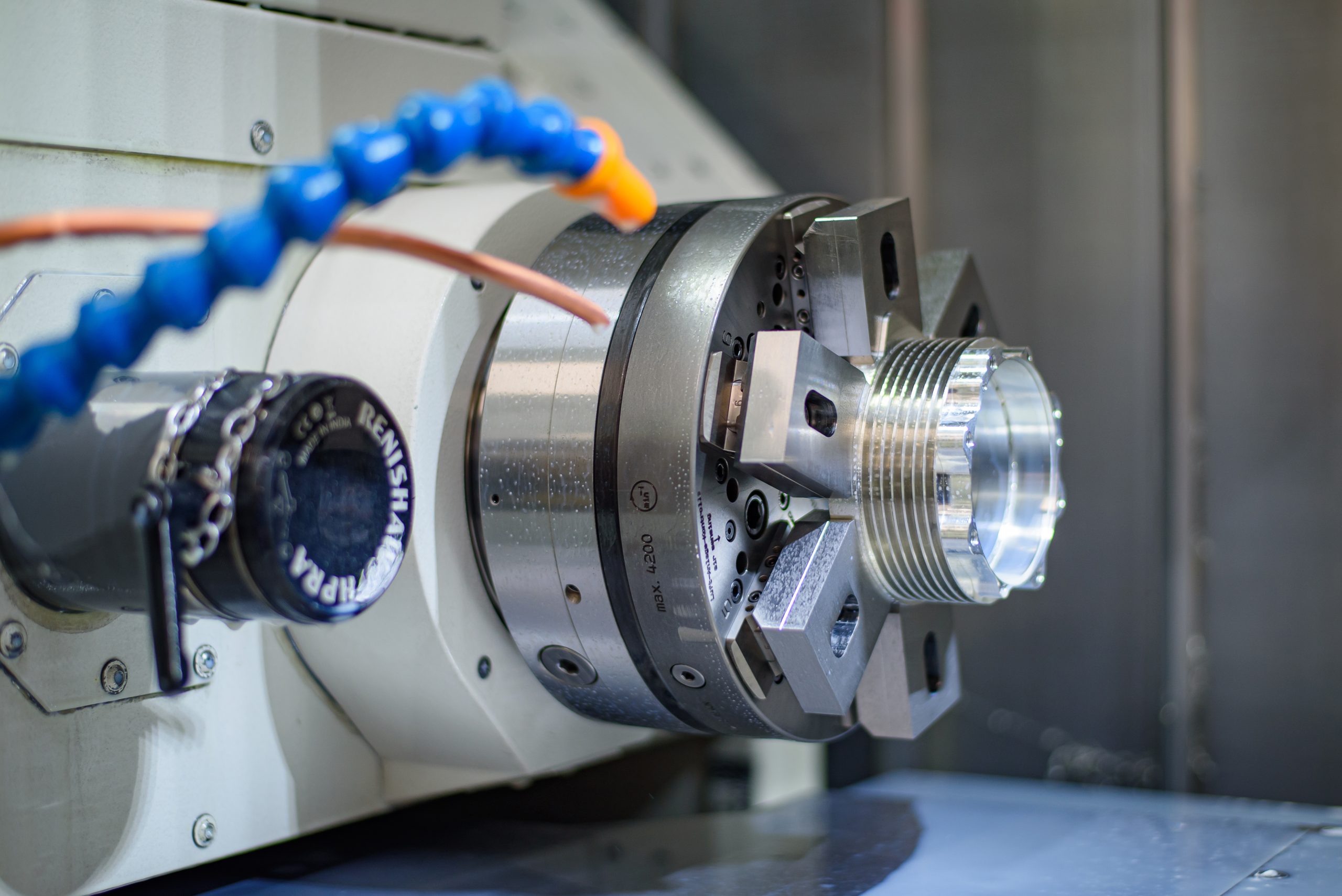

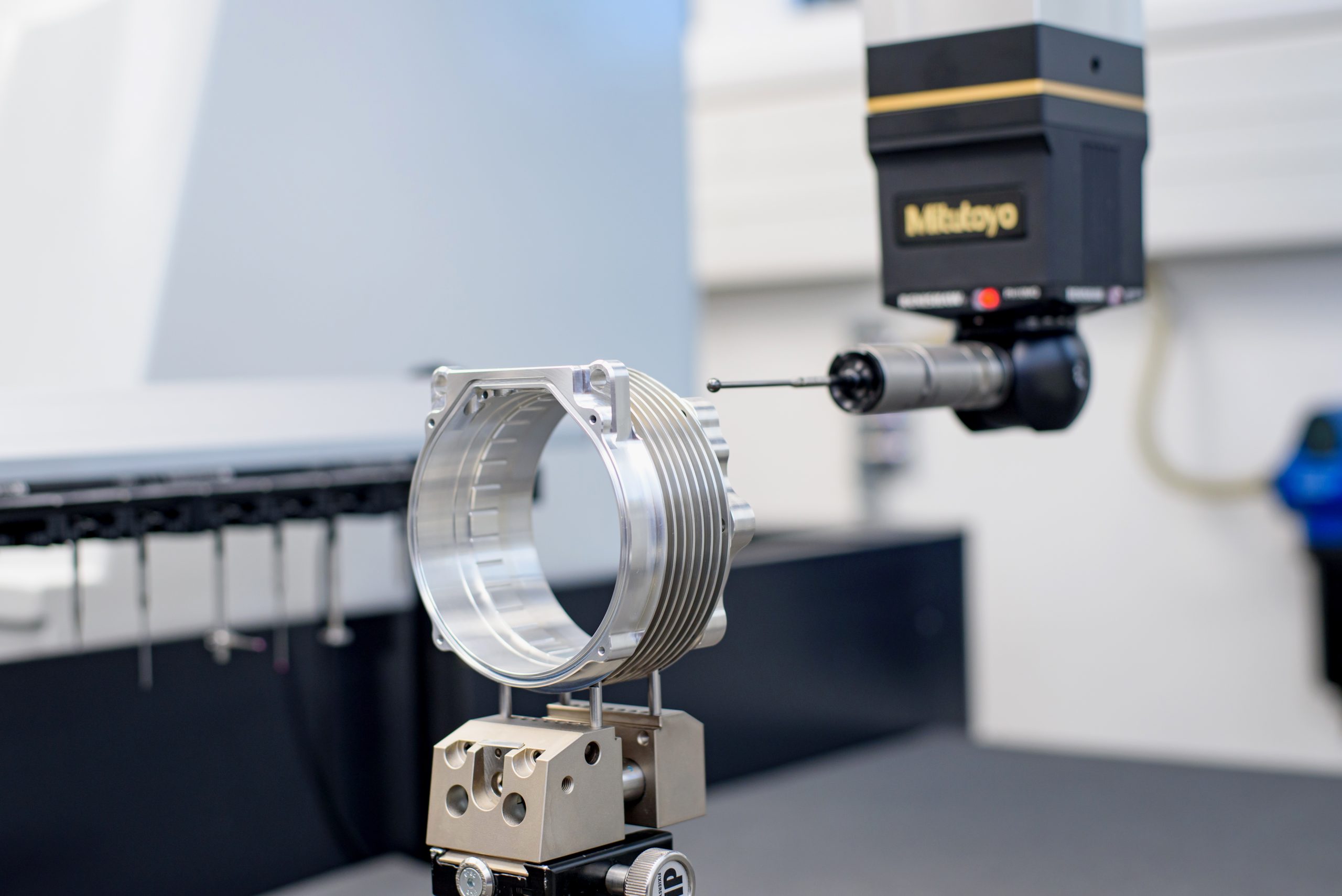

Ypsotec specializes in precision CNC machining, including turning and milling components. Their expertise covers longitudinal turning, multi-spindle machining, short part turning and chuck turning along with 5 axis CNC milling.

Ypsotec operates facilities in Switzerland and the Czech Republic, providing high-quality, cost-effective manufacturing solutions. Their services cater to various industries such as automation, medical technology, robotics, and aerospace, ensuring high precision and timely delivery.

The Challenge

Effective cooling and lubrication are critical in CNC machining to maintain precision, extend tool life, and ensure surface finish quality. While operating the CNC machines Ypsotec wanted to improve some of the issues that historically occurred. During the manufacturing process the company wanted to protect operators from skin irritation, facilitate better cleanliness of parts, extension of the life of the fluid in the central tank, thus decreasing excessive waste whilst of course gaining operator acceptance.

After considering multiple solutions, Ypsotec has decided to take trial of Q8 BRUNEL XF 741. The results were great, and implementation was phased in across the Czech site.

Q8 Brunel XF 741

Q8 Brunel XF 741 is a high-performance, biostable water-soluble cutting fluid designed for metalworking applications. It combines high-purity synthetic base fluids with lubricity additives, providing excellent wetting, detergency, and stability in various water conditions. Suitable for high-speed machining of ferrous and non-ferrous materials, including automotive and aerospace aluminum alloys, it resists bacterial infection, offers extended fluid life, and reduces maintenance. It is environmentally safe, free from harmful substances, and compliant with TRGS 611 standards.

The Benefits

As of now the product has been in the central system for 12 months without the need for any additive additions. The adoption of Q8 BRUNEL XF 741 brought several notable improvements:

- Operator safety: The operators are very satisfied with the product in use as it creates a cleaner working environment and mainly because of its gentleness on their skin. The liquid does not irritate the skin or the respiratory tract.

- Biostability: Due to the coolant, the product stayed in the central tank without biocide additions for over twelve months therefore cutting down on any potential HSE issues.

- Cleanliness and Waste Reduction: The components machined using Q8 BRUNEL XF 741 were notably cleaner, whilst also reducing waste.

Conclusion

Ypsotec successfully tested and subsequently adopted Q8 BRUNEL XF 741 highlighting the importance of selecting the right coolant for optimizing CNC machining processes. By embracing this coolant, the company was able to improve their production, elevate their efficiency, and provide a safer working environment for their operators.

Petr Šaloun – Production Manager at Ypsotec

„In my opinion this is the best coolant we have had the chance to use and we have historically tested many competitor coolants. “

To learn more about Q8 Brunel XF 741, its benefits, and applications, please visit the product page.