In close collaboration with Q8Oils, custom manufacturing company Mariasteen has made a significant step in optimising its production process. By switching to Q8Oils coolant, the company has not only observed operational improvements but also continued to provide a safe and pleasant workplace for its operators.

Customized Metalworking

Located in Hooglede-Gits, Mariasteen has firmly established itself as a reliable and valued partner for numerous companies at both national and international levels, consistently tackling challenges head-on. This success is attributed to ongoing investments in advanced technology, an unwavering commitment to quality assurance, and a broad range of specialized services.

Koen Deleersnyder, Assistant Production Manager, explains:

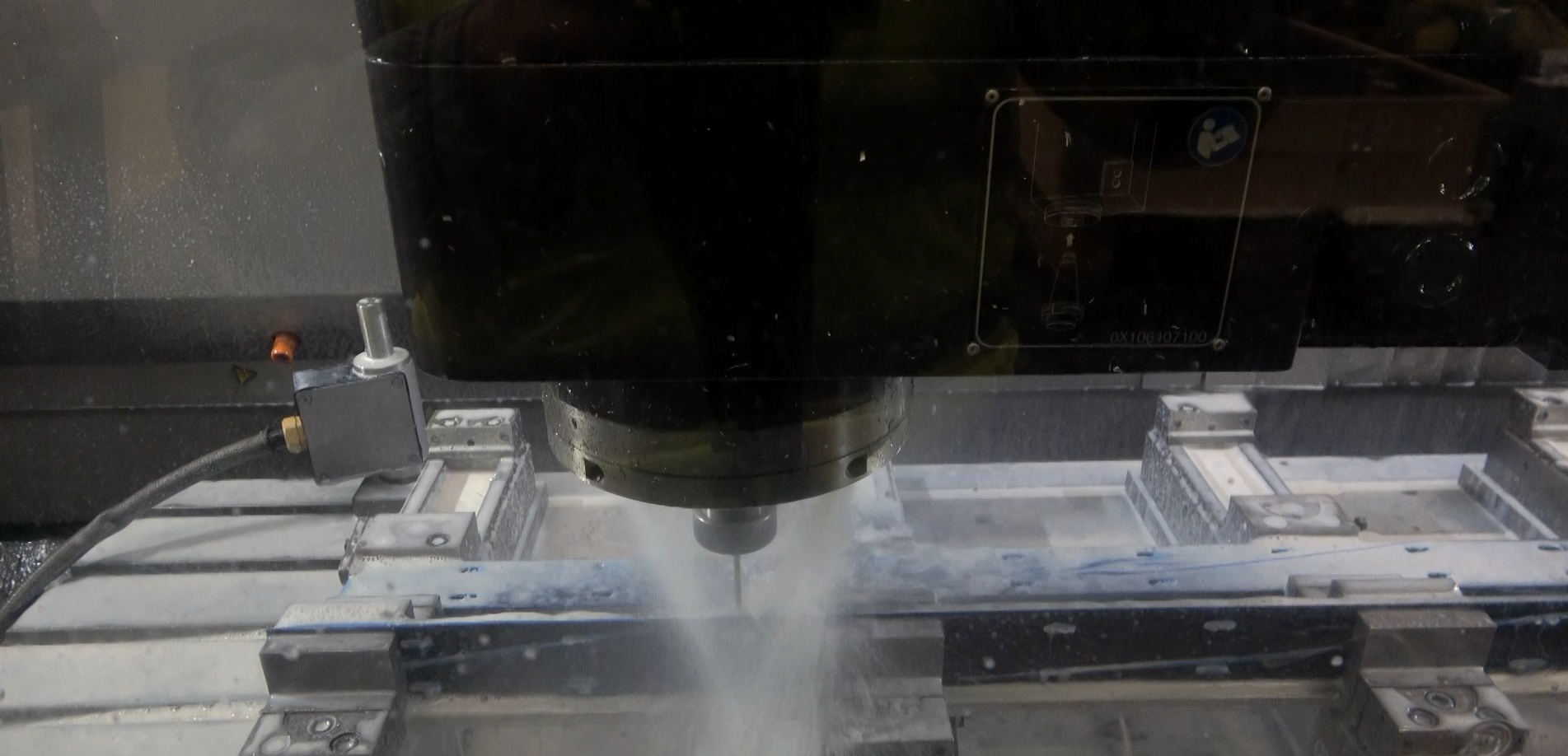

“Our metalworking department offers an extensive and advanced range of capabilities. We utilize state-of-the-art CNC techniques for milling, sawing, and drilling. In addition, we deliver high-quality TIG and MIG welding, along with bending operations for various materials, including steel, aluminum, and stainless steel. Our service portfolio is further enriched with laser cutting, galvanization, electrical assembly, woodworking, and more. Thanks to this broad spectrum of activities, Mariasteen truly serves as a one-stop shop.”

Need for Thermal Management

“The friction between tools and materials generates significant heat, leading to thermal deformation, accelerated wear, and even tool breakage. Using the right coolant effectively dissipates heat, enhances lubrication, and reduces the risk of cold welding,” Deleersnyder explains.”

“Moreover, it was crucial for Mariasteen that the coolant is safe for employees and easy to use. In our view, optimal coolant is an investment not just in product quality and processes but also in the well-being of our people.”

Q8Oils as a Facilitator

Over the years, Mariasteen has worked with various coolants, often having to adjust formulas due to new regulations and other factors. Their search for a new, reliable supplier ultimately led to Q8Oils.

Thorough Testing Period

Before fully transitioning to Q8Oils coolants, a rigorous six-month testing period was conducted on two CNC machines. The results were highly positive. “The Q8Oils product significantly extends the lifespan of our machine baths, reducing the disposal of used products and downtime. Thanks to its excellent biostability, we no longer need to drain the baths before holidays to prevent bacterial growth,” Deleersnyder says.

The sustainable properties of Q8Oils coolant align perfectly with Mariasteen’s core values. Having repeatedly earned the VOKA Sustainable Entrepreneurship Charter, the company actively works to make its production processes more sustainable. Switching to Q8Oils coolants was an important step in this effort.

Frederic Van Hecke, Business Development Manager at Q8Oils, emphasizes:

“For customers, it’s crucial that coolants have a long lifespan and retain their effectiveness. The longer the product lasts, the less waste is generated, and the lower the costs.”

Completely Odorless

Additionally, the coolant contributed to an improved working environment. Its pleasant, neutral smell created a more enjoyable atmosphere on the shop floor, enhancing employee well-being and motivation.

Frederic Van Hecke, adds: “A good coolant serves multiple functions. It must cool, lubricate, protect against rust, clean, ensure good chip evacuation, extend tool life, and enable higher work speeds. Beyond this, it can also help improve environmental impact and workplace health. Operators who handle the product daily should not experience any discomfort.”

Continuous monitoring and reporting

Continuous monitoring and reporting

Following the successful test phase, Mariasteen decided to integrate Q8Oils coolants on a large scale into its operations. The collaboration includes proactive, bi-weekly monitoring of coolant concentration in each machine, ensuring timely detection and adjustment when needed. This approach guarantees long-term, trouble-free machine operation, allowing Mariasteen to focus on production without concern.

“We are extremely satisfied with Q8Oils’ professional support, which includes regular and precise measurements. This enables us to confidently and consistently utilize our machines. The collaboration is undoubtedly a great success,” concludes Deleersnyder.”

If you have any further questions about Q8Oils coolants, do not hesitate to contact us.