When it comes to the cold rolling of copper and copper alloys strips, achieving high surface quality is crucial. However, despite the best efforts, various surface defects can still occur, and one of the most common ones is known as stains. These discolorations can appear on a specific part of the strip surface, causing a negative impact on its overall quality.

In this article, we will delve into the topic of stains, exploring their causes, characteristics, and how to investigate them.

Where do stains come from?

Stains on copper and copper alloy surfaces can have a multitude of origins, making their identification a challenging task. The complex process of cold rolling involves several steps, which can obscure the source of the stain until later stages of production.

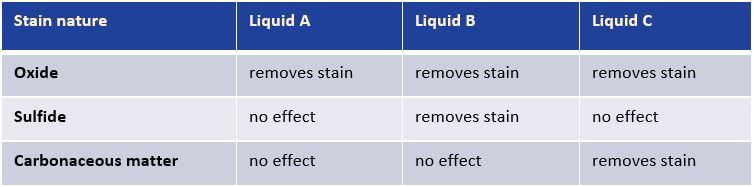

To help identifying the root cause of a stain, Q8 Oils R&D has developed a test to scrutinize it in detail. This test can analyze the composition of a stain and distinguish between different types, including those caused by oxidation of copper, carbonaceous matter, or copper sulphur substances – which have been the historical culprits of stains on copper alloys.

Test to identify the root causes of stains on copper and copper alloys.

Q8 Oils R&D conducts its stain analysis test using four copper alloy strips measuring 85x15mm, with the targeted stain partially present on each. One of the pieces remains untreated as a reference, while the other three are dipped into separate investigation liquids – A, B, and C.

Visual inspection of all four pieces together determines whether the stain is removed or persists. The resulting matrix table is then used to identify the type of stain based on the outcome of each test.

What does the nature of the stain means?

Once the nature of the stain has been identified, the next step is to determine when it was initially formed. Nowadays, copper sulfide stains are now rare, since active sulfur is no longer used in copper alloy processing. Copper oxide stains, on the other hand, can form at high strip temperatures in the presence of oxygen, often caused by factors such as high reduction rates, excessive speeds, inadequate cooling, or a combination of these factors. Carbonaceous stains, which are caused by the presence of carbon-containing materials like oil, plastic, and paper, can form when the copper alloy surface is exposed to high temperatures. For example, if too much oil is present during annealing, not all of it may evaporate in time, leaving residue that eventually carbonizes on the surface of the strip.

Remarks

Q8Oils collaborates closely with customers to enhance their cold rolling process by developing tailor-made oil compositions. A critical aspect of this improvement process is gaining a thorough understanding of potential defects, such as staining. Our stain analysis test can help identify the root cause of stains on copper alloy strips, providing valuable insights to further optimize your production process.